Fall Protection Systems - 3 Misuses to Avoid & How to Fix Them - Our Guide

Posted by Howie Scarboro - CEO Fall Protection Distributors, LLC on Feb 13th 2020

People working at the height of four feet above the ground or higher are required to wear fall protection to ensure their safety. While the exact minimum height may vary by state, anyone stepping off a ladder onto a roof requires an OSHA safety plan and proper fall protection equipment.However, equipping yourself with fall protection gear isn’t enough to save you from a fall - improper use of the tools, and inadequate training can increase the risk of acquiring fall injuries.

That’s why arming yourself with rudimentary knowledge regarding the industry standards of fall protection equipment is a must for all workers, especially if you want to steer clear of potential mishaps and OSHA violations/fines. With that in mind, the guide below should help you avoid common fall protection misuses:

1. Misuse of Snap Hooks

There are many uses for snap hooks but there are dangers that come along with them.Newer regulations have made them safer and better at avoiding accidental disengagement.Make sure all snap hooks are up to current ANSI standards.Since 2007, all fall arrest snap hooks are required to have a minimum gate face load and side load of 3,600 lbs.If this is not stamped in your snap hooks, they are now illegal to use and should be replaced immediately.

For instance, opting to skimp out on an additional connector can be dangerous as the strength of the worker’s anchorage may be risky. That’s why all employers must know the gate strength of their rebar snap hooks and understand its stress points to ensure a solid attachment.

2. Inappropriate Anchorage Connections

Using energy-absorbing lanyards as anchorage connectors increase the risk of fall injuries as most fall arrest lanyards are not designed to wrap around a structure and back to itself.Only use pass-thru straps designed and reinforced for anchoring to objects to avoid abrasions to the strap.

Even if the lanyard is meant to wrap on itself, employees must remain alert and understand the dangers of securing to a piping system, beams, guardrail, or ductwork. With that in mind, you can mitigate potential misuse by ensuring there is an unobstructed load path between the anchor and the worker.

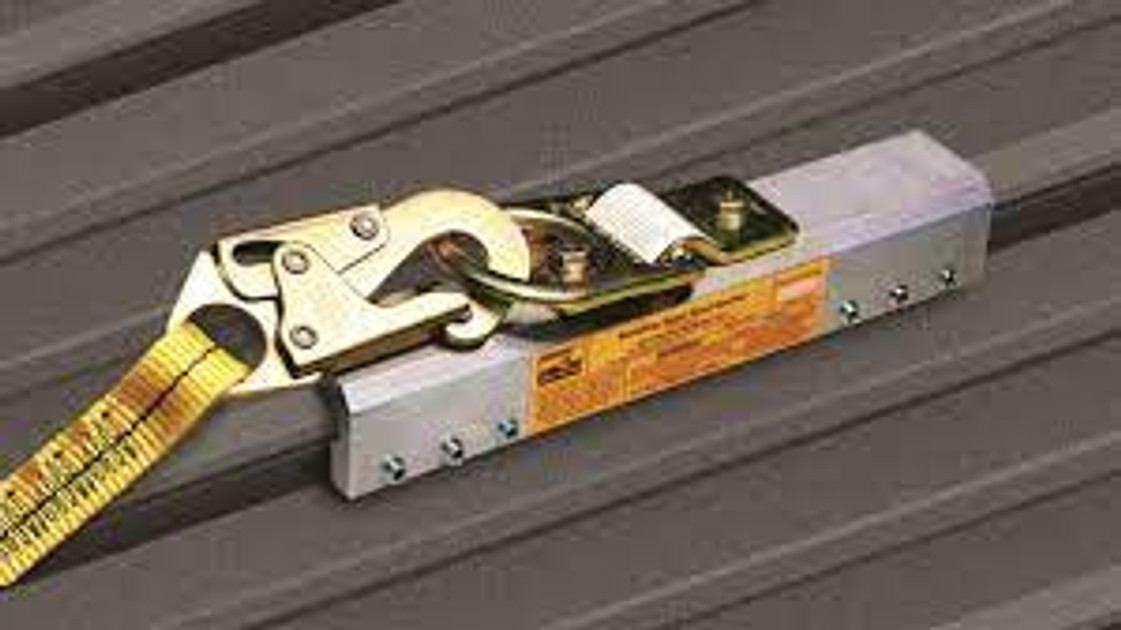

3. Insufficient Anchorage Strength

The anchorage strength is one of the most crucial factors in fall protection equipment as it is designed to support the person wearing it. That means that workers should know that snap hooks or anchorage straps should only connect with certified anchorage points.

However, finding an anchor point with sufficient strength can be tricky as some materials have a protecting coating that keeps employers from evaluating the core material. OSHA Competent Person trained workers should be able to identify safe and practical, noncertified anchorage point is sufficient to protect the heaviest worker on the job. An OSHA Qualified Person should be capable of designing certified anchorages.

Another way to ensure the anchorage has sufficient holding power is to choose designs that cater to different loading possibilities with an average arresting force between 900 to 1,350 lbs.

In Conclusion

Establishing an OSHA compliant safety plan including fall protection is legally required in the United States to ensure the safety of all workers. The guide above should help shed some light on the common faulty practices regarding fall protection equipment, so taking the time to correct potential mistakes can make a world of difference in the worker safety.

We provide fall prevention equipment that’ll keep you safe on the job, get in touch with us today to see how we can help.