SSRA1 Install Video

Posted by Howie Scarboro - CEO Fall Protection Distributors, LLC on Oct 4th 2023

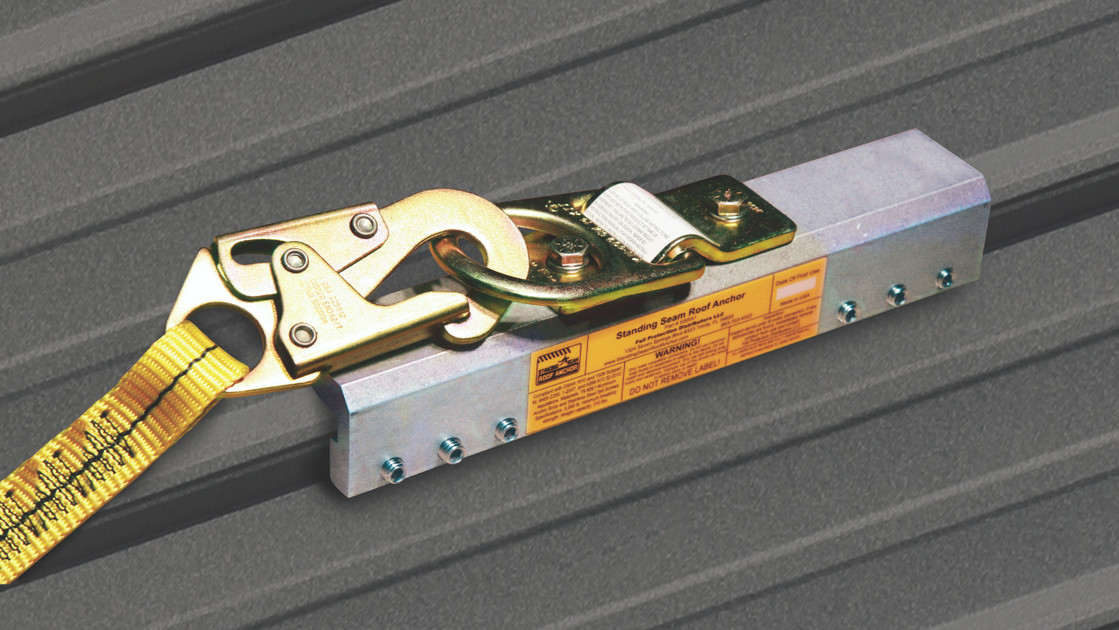

I'm Howie Scarboro and I'm the CEO of Fall Protection Distributors. We're the master distributor for the Standing Seam Roof Anchor. So today we're gonna do a very simple install video for people that have just purchased the anchor. The way that you see the anchor, this is the way that it arrives. It's gonna be pre loaded with 12 stainless steel cup tip set screws. It's already gonna have the safety stickers installed and it's already gonna have the D ring installed. By now you should have already read your owner's manual cover to cover. You should have already got the anchor into service by doing your date of first use, doing your initial inspection.

Part of that includes these two top bolts. You want to check torque on these before every use. These are 9/16th inch and these need to be torqued to 90 inch pounds minimum, not foot pounds, 90 inch pounds. Same as these cup tip set screws. So once you've done all that, you really just need two tools to install this. You need your typical screwgun. Hopefully, your screwgun has a clutch. That comes in handy and, and certainly helps speed up the installation. And then you also need a torque wrench. What they call a micro torque wrench that is capable of reading down into inch pounds, this one is a 1/4" drive. I have a 1/4" drive socket bit with a 3/16" hex bit. And that will just be used for the final torqueing. So one thing to note, we are using an 1.5" tall seam.

I'll show you a little trick we use to speed up installation. But on seams that are inch and a half or shorter, the installation is very simple because the clamp itself is going to sit flat down on the panel. So you don't have to worry during installation on taller seams. When the clamp is up off of the panel, you have to be careful that you don't get it tilted to one side during installation. You have to hold it nice and straight. So, on 1.5" or shorter it's very simple because it does sit pretty much flat down on the panel. One tool you might want to have in your toolbox that helps speed things up is just a pivoting bit holder. These are eight to ten dollars. This happens to be a DeWalt. This certainly helps because on these shorter seams, these set screws can get close to the panel. And it's sometimes hard to get your screw gun lined up with the screw, so these pivot bits come in handy, so pick one of those up.

And then we include a 3/16" bit with the anchor, it'll typically be taped on top. This is just a starter bit.You can get longer ones, like I said, you can get the pivot. This is a nice accessory to have for shorter seams. But, we give you a starter bit, but you know, pick up a couple extras, that should be all you need. One trick that we do to speed up the installation is, I'm left handed, so what I do is if you notice the set screws, this is what's called pre loading. I've already set one side of the anchor, these six set screws, to about the position, when this is done being torqued, the seam's gonna be in the middle and these screws are gonna squeeze in. So that the panel is squeezed between the two set screws. So I preload these six. I want to put those on the right side of the seam so that my screw gun is in my left hand, which is more comfortable for me.

So, go ahead and get these in a nice straight line. About, just off of center, about where the finish position is going to be. And then you just set that over the seam. You want to make sure, when you locate this on the seam, you need a competent person on site that knows the proper location to put the anchors. (If you want to learn more about Competent Person Training, read this recent article highlighting the benefits.) you want to be six feet from any fall. areas from any edges of the roof. You don't want to be within six feet of the end of the panel either. So make sure that you have a proper OSHA approved safety plan of where to mount these anchors before you do anything. Once we have it in place, it's about a two minute installation once we start. One is we're going to snug up these six set screws with the screw gun.

I know on my personal screw gun with this clutch, that with it set 15, puts me actually at about 75 or 80 inch pounds. So we're going to be torqueing these cup tip set screws today to 90 inch pounds. So your gun's going to be a little bit different. So I'll just take my flex bit, load it up, and we're pretty much ready to go. So this is our starting position, like I said, I've got my screwgun in my left hand because that's what's comfortable. And what I'm going to do is snug up these six set screws and I'm going to alternate. I'm going to go here, here, three, four, five, six, and then I'm going to go around all twelve screws and I'm going to set everything to 90 inch pounds. Okay, so everything's snugged up.

Set that aside. Now I have my torque wrench, and like I said, this is a micro torque wrench. This reads down into inch pounds. We're going to 90 inch pounds, not foot pounds. With these cup tip set screws, we have two types of set screws that we're certified to use in this. One is the cup tip, all stainless screw that is out of the box with those cup tip set screws already loaded. You can also use an optional set screw that's a nylon tip. It has a nylon bushing in the end. If you use the nylon tip set screws, this process is going to be the same, except you're going to go to 180 inch pounds on the nylon tip. We're using just the regular cup tip, so it's 90 inch pounds.

That's all written on this on the safety stickers. So just remember on your torque, whichever set screws you're using, check the torque, and it is very important. That is the number one rule of this anchor, is it has to be properly torqued to work. I just have my 1/4" drive 3/16" hex bit because I have a 1/4" inch drive torque wrench. You could have a 3/8" or even bigger torque wrench but that's what I happen to have here. So, okay, so those are torqued. Switch over to the other side.

And there you have it. That's a properly installed standing seam roof anchor. about two minutes without a bunch of extra talking. So whatever you're going to be attaching to this, typically it's going to be a vertical lifeline. Clip in, you're ready to go. So if you have any questions on this, feel free to give us a call. 863-703-4522.